The Rivarossi

Motor

The Rivarossi

Motor

The Rivarossi

Motor

The Rivarossi

Motor

Yes, the much maligned Rivarossi N scale motor. I have even seen the epithet "junk" applied to them. OK, so they would never be considered state-of-the-art nowadays but they were still an important part of being able to even HAVE powered N scale models right? Actually, the only part that seems to consistently cause trouble is the commutator form. Rivarossi used a plastic that wasn't quite up to snuff in handling the heat generated by the motor. In time (sometimes in a surprisingly short period of time) it either gets brittle with parts falling away and allowing the segments to displace or suffers complete melt-down. There was an effort to eliminate this malady in that the later motors were equipped with a little more substantial form and maybe made of a different or modified plastic. For the most part, I believe it worked because I have rarely seen any of the later forms that have deteriorated.

Anyway, below are some specs., a description of the motor itself and information regarding maintenance and repair of these odd, but interesting, little powerhouses.

| Motor Length with Cap In Place (excluding shaft) | .76" (19.5 mm) |

| Can Diameter | .57" (14.5 mm) |

| Can Length | .49" (12.5 mm) |

| Can Length Over Bushing Extension | .55" (14 mm) |

| Motor Shaft Diameter | .058" (1.5 mm) |

| Motor Shaft Length (except 0-8-0, 0-4-0, and Cow) | approx. .905" (23 mm) |

| Commutator Form Length | .180" (4.6 mm) |

| Commutator Form Diameter Over Segment Mounting Area | approx. .120" (3 mm) |

| Brush Holder Outside Diameter | .100" (2.54 mm) |

| Brush Diameter | .063" (1.6 mm) |

| Brush Length | .125" (3.18 mm) |

| Coil Wire Diameter | .003" (.08 mm) |

| Turns per Coil | approx. 300 |

The Rivarossi motor consists of:

1. The main motor body, which is the metal "can" and includes one of the shaft bushings. This view shows the inside of the can.

This view shows the side of the can with the "vee" shaped slot for the cap.

2. The ring magnet, which lines the inside of the motor body. This is made out of a rubberized magnet material and can be seen in the image above of the inside of the can.

3. The motor cap, which is the black plastic piece on one end that includes the other shaft bushing. On the left is the cap as used in the E8s, C-Liners, 0-8-0s, Pacifics, and Mikados. In the middle is as it's used in the 0-4-0 and on the right is as used in the SW1500 Cow.

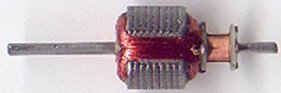

4. The armature, which is the complete assembly that spins inside the motor.

5. A washer (or more than one) on the shaft at each end of the armature. Don't lose these as they center the armature inside the body so the brushes are centered on the commutator. Of course, they are also the thrust washers.

6. The brushes, springs, and holders, which supply current to the commutator and on to the windings.

![]()

The armature consists of:

1. The windings (3) and the core on which they are wound that is lined with plastic so the windings don't short to the core. Note that earlier motors have plastic insulation only on the ends of the laminations. The windings don't contact the metal in the inner part , however, because the end plastic extends out beyond the metal laminations, holding the wire away. The core is the laminated metal assembly and you can see the three "lobes" of it around the outside. These lobes are very close to the ring magnet when the motor is assembled. Here is an armature without windings.

early later

later

2. The commutator assembly, which is a two piece (front and rear) plastic form and the three copper "plates" mounted around the outside of it. This can be seen on the right end of the shaft in the image of the later armature core above.

3. The motor shaft on which all of this is mounted.

The way this whole thing works is:

Current goes through one brush to one commutator segment and through one winding and back through another commutator segment and out through the other brush. While the one winding is energized, it is attracted to the opposite polarity on the ring magnet which is polarized North and South.

This starts the motor turning which brings the next commutator segment in line with the brushes and energizes the next winding. This winding is attracted just like the first one and the motor continues to turn. This keeps happening over and over again and the motor spins. The higher voltage fed to the motor, the faster it spins because the windings are attracted more vigorously to the opposite polarities on the ring magnet (the windings become magnets themselves when they are energized).

This is a bit of a simplified description of the action because magnetic repulsion is as much a factor as attraction, but the gist is as above.

The construction of the winding/commutator assembly goes like this:

A winding is soldered to one commutator segment and, after being wound around its core about 300 turns (I believe that earlier motors have fewer turns but I haven't counted them, it just looks like there are fewer), is soldered to the next commutator segment. The next winding is soldered to this same segment, wound 300 times around its core and soldered to the next segment and so on.

You will see two wires attached to each commutator segment which are the beginning of one winding and the end of another. These MUST be connected, of course, or the motor won't run.

Variations

For variations regarding this motor, please see the EMD E8s page. The variations concern only appearance, modifications, and adaptations for different model locomotives. The basic motor is the same throughout.

Disassembly

All this is best done with the aid of a magnifier or even a microscope.

Before disassembly, I connect the motor to power to note if, or how, it runs so I will have clues as to what to look for when it is apart. No current draw indicates one or more open windings (or missing brushes!). High current draw indicates shorted windings or brush material between the commutator segments. If the motor appears to want to run, but is stuck, it indicates that one or more commutator segments has/have come loose and is/are hitting a brush or brushes or the ring magnet is so badly swollen that the armature has become immovable within it. If there is mechanical noise, it indicates that the armature is rubbing on something like the ring magnet or the brush holders are rubbing on the inner side of the commutator form flanges.

The first step (after the motor has been removed from the locomotive, of course) is to remove the brush holders, brushes and springs. The holder with the ground contact should always be installed on the side of the motor with the "vee" shaped motor cap slot (see below). I use a small pair of needle nose pliers to grip the head of the holder and kind of twist it out. Sometimes the brushes will stay in the motor as the holders are pulled out. Either tap them out of the motor or extract them with tweezers, depending on whether or not they are stuck from goo. Be careful, of course, as these tiny parts (especially the springs) can go flying off into the nether world, never to be seen again!

Next, merely pull off the motor cap which is a press-fit into the can. The motor can has two slots into which the cap fits. One of these has a flat lower edge and the other has a "vee" shaped lower edge. These are mainly to get the motor oriented correctly for proper rotation direction with a given polarity. If you want the cap reinstalled the same way when you reassemble the motor, note which side the "Rivarossi" logo (on the cap top) is on relative to the two slots in the can. I always keep the two slots to my right and left while I have the motor disassembled (vee shaped to my right) and note whether the logo is originally toward me or away from me. As you remove the cap, note whether the thrust washer (or washers) stay on the motor shaft or in the cap. This is important as it is very easy to overlook and lose them. Remove any washers from either the cap or shaft and put them in a safe place and note how many there are.

Further disassembly depends on the application for which the motor is used. The Pacific and Mikado motors need only to have the plastic coupling pulled off of the shaft to remove the armature. The E8, C-Liner, 0-8-0, and 0-4-0 motors need to have the worms pulled off which is not as easy. I don't remove the armatures in these motors unless I absolutely have to. The 0-8-0 and 0-4-0 worms can be removed with an appropriate gear puller but the E8 and C-liner are different because the worm has a closed end so there is nothing for a gear puller shaft to push against. The method I use is to pry the worm off with two screwdrivers between the worm and either side of the motor can. Some of the worms are real bearcats to get off so when doing this, the other end of the shaft should be clamped in a vise so the shaft is not pulled through the armature instead of the worm coming off. Don't worry about squishing or otherwise damaging the shaft. They are really tough. I don't like doing it this way because sometimes the worm gets a little marred (although this can be touched up with a file and crocus cloth). Anybody know of a puller that would work for this? If the worm is a tough one to get off, I ream it out a little bit before reinstalling it so it will be easier to get off if there is a next time.

There is no worry about magnet strength being reduced when the armature is removed from these motors. When the armature is pulled out, however, look again for thrust washers, either on the shaft or remaining in the can on the bushing or stuck to the ring magnet. Again, note how many there are and don't lose them.

Refurbishing

If all the parts appear to be in good condition, restoring good operation is mostly cleaning and relubing. These motors have a tendency to get a lot of brush debris build-up because of their enclosed nature. I have also seen a lot of gooey gunk build-up from previous owners' overzealousness in lubricating them. To clean this stuff off from the armature (especially the commutator) and cap, I first use a toothbrush and a judicious amount of mineral spirits (use a light touch, of course). This is followed by a wash in isopropyl alcohol to remove the mineral spirits. Pay particular attention to getting all the material out from between the commutator segments. This can be a cause of high current draw because it makes a short circuit between the segments. After the armature appears clean, I force dry it using a small air compressor. This gets any remaining liquid out from crevices.

After cleaning, inspect the armature for detached winding connections to the commutator and to determine the condition of the commutator itself. The form should be intact, still round, and the segments clean. A small amount of brush material remaining on the segments themselves won't hurt anything but a severe build-up will require removal by crocus cloth followed by another cleaning.

It is also good to inspect the general condition of the windings themselves for breaks or wear around the area of the can-side bushing. The main thing to look for is windings overlapping or too close to the area where the thrust washer seats. They will eventually be ruined when the armature rotates if left to rub on the washer or bushing. I use the shaft of a small jewelers screwdriver to push the windings away from this area. You could use anything that is small and dull to do this. Of course, be careful not to damage the windings or insulation.

Ideally, you should check the electrical resistance between each two adjacent commutator segments. There should be 20-25 ohms between each two with all the windings attached and having continuity. Each winding alone has about 30 ohms resistance but when they are all connected, Ohm's law comes into play. If the winding across the two segments measured is open, there will be about 60 ohms measured because you will be measuring the two other coils in series (assuming they are good). If either of the other two windings other than the one you are measuring is open, there will be about 30 ohms resistance because you will be measuring that coil alone. If you get infinite resistance no matter what, it's pretty obvious that all the windings are open. Of, course you will need access to a ohmmeter to do these tests.

Another way to check them, though, is with two wires attached to a power pack through an ammeter. Set the speed control on the pack to a fairly low (about 1/3 throttle) setting (technically at 4 volts if you have a voltmeter attached - but it should be fairly close at 1/3). Touch the wires to two adjacent commutator segments. The current draw should be between .20 and .25 amps if all the windings are good. Repeat this for the other two windings, touching the wires to the two commutator segments for the winding being tested. A current draw of about .10 amp would mean that the winding across the two segments you are contacting is open because the current would be flowing through the other two coils with twice the resistance (hence, half the current). High current draw indicates that one or more windings has probably been heated to a high enough temperature to melt or burn the insulation and short circuits are occuring. This can usually be seen by a discolorization of the wire.

Generally, a good number to remember is 20. If all the resistance measurements are about 20 ohms or the current draw is about .20 amps across all adjacent segments, things are OK.

The brush holders, springs, and contacts can be cleaned the same way as the armature and cap. I usually just clean the brushes themselves by rolling one between my thumb and index finger while the brush is wrapped in paper towel. If the brushes appear oily, I use alcohol to clean them. DON'T use mineral spirits or other petroleum based solvents.

I don't use any solvents to clean the can. I have seen ring magnets that are ruined by being softened and swollen and since I don't know whether it is caused by an inherent defect in the rubberized magnets themselves or by overzealous lubricating again, I think it's safer to just clean them with a dry paper towel or cloth. The can usually isn't absolutely filthy anyway. The bushing can be cleaned in it's inside diameter by forming a little cone on a corner of a paper towel and inserting and twisting in the bushing. Compressed air is always good to remove any remaining debris.

Problems and Repair

By far, the most common problem with this motor is the commutator form breaking down, or even melting, from heat. This form must keep the commutator segments in position or they will fly away towards the outside of the motor due to centrifugal force. The segments are kept in position with tabs on each one being inserted into slots on the form. The slots toward the motor windings are the most likely to be ruined from heat. When inspecting the form, check to see if any of the segments are loose, even though the slots appear to be in good shape. Sometimes it's not starkly apparent that there is deterioration and it is a good idea to affect a repair before things get worse.

Another thing to look for is segments which have moved out of parallel with the shaft due to temporary softening of the form. I do this by viewing from the side of the armature and across the segments to see if either end of the segments has moved toward the outside of the form. This can be corrected by using a soldering iron very carefully to press the segment end back into place.

If the slots are bad and the segments have dislocated or are loose, it is a matter of reattaching the segments to the form. I use 5 minute epoxy applied with a small tool such as the tip of a very small jeweler's screwdriver. I use a bit of small diameter wire wrapped around the segments and twist-tied to hold them in place while the epoxy hardens. I apply the epoxy to the areas around where the original slots were and actually epoxy the form to the windings too to keep the commutator from spinning on the shaft. If the form is not cracked and seems tight enough on the shaft so it won't spin, it isn't necessary to do the latter. Excess epoxy can be removed with a sharp blade after the epoxy has set semi-hard but before it is fully cured. As far as orienting the form around the shaft, there must be a tab from each segment located between two windings. Or, another way to put it is to say there must be a gap in the segments centered in front of each winding. Of course, you want to be sure that the windings are soldered to the tabs first or make sure you don't get any epoxy on them. I will also re-state here that the parts in question must be really clean so get out those solvents and scrub (not too hard though).

After the epoxy has cured (I usually allow a couple of hours) I use 600 grit sand paper to smooth the segments out followed by crocus cloth. This is done with the other end of the shaft clamped in a vise, using narrow strips of sandpaper, and using a motion not unlike one might use when drying your back with a towel after a shower. It's important to try and keep the sanding even so the commutator stays round. This is neccesary for good low speed performance. The less resistance in turning between the brushes and the segments, the better. If the commutator is out of round, the brushes will have to ride "up" the high spots and this adds mechanical resistance. After the commutator is repaired and polished, clean it with alcohol to remove residue. It is important that it be very clean.

If the form is too far gone, a new commutator form can be made from acrylic plastic (plexiglass) if you have access to a lathe. I use 1/4" rod (you could use 1/8" rod and it would be really close to perfect) and turn it down until it's the right diameter (approx. .120" -.125" but I custom fit the segments). Then center drill it (motor shaft diameter is .058"). The length of the form is .180". Then epoxy the segments onto the new form evenly spaced around it, true it up, install on the shaft, and solder the wires. I have resurrected several of them with really badly melted forms this way.

It may be that one or more connections to the commutator segments have merely detached. In this case, they just need to be resoldered. The problem can be getting enough length of wire from the winding. If the detached wire is at the end of the coil, you can unwind it one turn, tin the wire and resolder to the segment tab. If the detached wire is at the beginning of a coil, it can be a frustrating adventure to get it reattached because you can't unwind wire that is buried in the coil. Rivarossi used two different ways of beginning the winding. On some of the motors, the wire is very short and goes right down into the coil at the commutator form. Fortunately, these rarely detach because of their length and positioning. But if one does detach, care must be taken not to break the wire off or it will mean rewinding. The other method they used was to start the winding so the wire goes into the coil at the end away from the commutator. This leaves a longer wire to the soldering point. You still can't unwind it to get a longer wire to work with but it is possible to add wire to the existing one to use.

Another fairly common problem is that of the ring magnet deteriorating. It gets soft, mushy and swollen so the armature poles rub on it. I have had some success in scraping away some of the inner surface to restore clearance but the ideal would be to obtain a good can.

Note: If you should ever have occasion to remove the ring magnet, it must be reinstalled correctly. The ones I have seen all have the "seam" where the two ends meet somewhere between the 12:00 o'clock and 1:00 o'clock position looking down into the can with the vee shaped cap slot to the right. If the magnet is not oriented correctly, the motor will turn in the opposite direction from what is intended.

When I first had to try to repair one of these motors years ago, it was a bit daunting, but I figured I had nothing to lose right? Now it has become a matter of routine and I have bought many old Riva engines that didn't run, very cheaply, and resurrected them.

Reassembly

Now that all the parts are clean and good, and the motor repaired, if required, the motor can be rebuilt to be a wonderful thing again.

Begin by taking the armature and placing the washer or washers that were removed back onto the shaft end towards the can bushing and pushing them all the way to the plastic end of the armature insulation. Put a little dab of grease (I used to use LaBelle oil here but the tolerances of these bushings seem to be a trifle on the loose side so now I use LaBelle 106 grease with teflon as they run quieter) onto the area of the shaft and washers to stick the washers to the assembly. If this isn't done, the washers will be pulled off from the shaft by the magnet as the armature is inserted into the can (there needs to be lube here anyway right?)

A note about lubrication: Atlas originally recommended using their "Formula XX" grease on gears and "Black Lube" on bearings (bushings) and axles. The "Black Lube" Seems to be a graphite-based lube. These may have been Rivarossi's lubricants that they used and recommended to Atlas. The Formula XX seemed to be OK and, generally, the Black Lube was OK too except that sometimes it seemed to be too high a viscosity and wouldn't work its way into the bearing or bushing. This was no doubt the cause of some of the Rivarossi engines to squeal at a relatively young age. I discovered that the squealing was usually caused by the bushing at the gear side of the motor being starved of lubricant even though there was plenty of it surrounding the bushing inside the can. Anyway, I now use LaBelle 106 grease with Teflon for everything and it has worked very well.

Now insert the armature into the motor can so the shaft goes through the bushing. Put the washers that were removed from the other end of the shaft back in place and add some lube here too. Position the motor cap and push it into place in the can so the motor shaft goes through it's bushing.

Put whatever was on the working end of the motor (gear or coupling) part way back on (only enough so you can get it off easily if needed) for something to hold on to. Now move the armature back and forth to check the end play. There should be very little (maybe 5 to 10 thousanths) but I have seen some with way too much. You can add washers (I found suitable ones at my hobby shop) to remove this excessive end play. If everything is OK, look into one of the holes into which the brush holders go using a bright light source such as a flashlight. This is to check that the commutator is centered in relation to the holes. Look to see that the commutator form flanges are not exposed into the hole or too near it. The flanges should be as equidistant from the center of the hole as possible. If this is not correct, the holders will rub on the flanges - not good. If you have to add washers to take up end play, the centering of the commutator has to be taken into account. Add washers to the shaft end that will keep things in the proper relationship.

Turn the armature by hand to be sure there is no interference. It should turn very easily with only magnetism as a resistance. If there is noticeable drag felt, the armature is rubbing on something and this must be corrected. The most likely cause is the armature rubbing on the ring magnet. Take the motor back apart to see if you can see marks on the magnet or magnet material on the armature indicating this. Sometimes, just rotating the motor cap 180 degrees will help.

Assuming the above to be OK, it's time to reinstall the brushes. Take a brush holder, with its contact or solder lug attached (note: there must be one of these present or some kind of spacer or the brush holder can go too far in and rub on the commutator segments), and drop the spring into it. Put the brush into the holder on top of the spring, orienting it so that the arc worn into the brush will coincide with the curvature of the commutator when installed. Now for the tricky part. Keeping the holder, spring, and brush in position so the brush won't drop out of the holder, insert the holder into the hole in the cap. This must be done in a smooth, single motion so you don't dislodge the brush. If the brush falls out of the holder, stop and try again. If you keep pushing the holder in if the brush has fallen out, you will crush the brush because it won't find its way back into the holder, but will hit the edge of the holder.

And now, a note about brushes. The original brushes and springs have not been available from Atlas or Rivarossi or Con-Cor, for that matter, for many years. Although you may find some on eBay (I got six sets once among some other A1G parts) or at a train show, they are pretty much a rarity. However, I found substitutes at my local hobby shop in the form of replacement brushes and springs for small slot cars (see, everything about slot cars is not evil). The brand I use is "Wizzard" (with two zees) and are as follows:

ST04 Stock Tyco Brush Springs-2 pr.

ST02 Stock Tyco Motor Brushes

OR

LLS02 Stock Life-Like Motor Brushes

I'm sure that these parts are just re-packaged items and I have had correspondence with another enthusiast, John O'Neal, who has found similar parts for a "Patriot" slot car still with the "Wizzard" brand name. The springs are a drop in replacement and the brushes are the same diameter but about 1.5 mm too long so they just need to trimmed to the correct length. They may even work if left at the original length but I didn't want to chance compressing the spring too much.

Another note: The original brushes can be used even if they are worn to about half their original length. Usually, if they stick out from the end of the brush holder a little, they will function. You can even carefully stretch the spring a little to accomplish this. Hold the spring at the very ends and gently pull. Don't over do it though.

Remember, the brush holder with the flat ground contact must be inserted into the hole that is at the "vee" shaped slot in the can and the hot brush holder must be inserted into the hole that is at the flat shaped slot.

Now that the brushes are back in, rotate the armature again to check for interference. Push up and pull down while rotating it to make sure neither of the commutator flanges rub on the brush holders.

If everything is OK, apply power and you should have a smooth, if not quiet, running motor. Current draw will be between .1 and .2 amps and speed change should be nice and steady as voltage is increased or decreased. One final tip: tap the side of the can while the motor is running to help re-seat the brushes to the commutator. You will notice an increase in speed and possible current drop as this happens.

Hopefully, this information will assist those who wish to try and repair, rather than replace, these motors.

Please contact me with any additions or corrections: dgosha@aol.com

Pick a page to go to: